OK, so there has been discussions on the Learn Camera Repair Facebook group about glues … a commonly recommended glue is Pliobond, which I have been using for many years. I was reading the Pliobond fact sheet from Ashland and it was a very detailed explanation about using this glue … well, this glue is not easily available outside of the USA, so there has been a number of the discussions about an equivalent.

I had mentioned in one discussion about a glue that I saw in a NobbySparrow video … Konishi G17. Triggered by this, Adam Fung, owner of Polar Bear Camera in the UK, recently imported Konisha G17 glue to try out. It appears this glue is popular with many Japanese camera repair people.

Adam is smart enough to know that if he was to stock a product is has to be a good product … so he sent a package to me in Canada to compare with Pliobond.

First test … the smell !!! This is very important to many people as they have complained about Pliobond’s odor (personally I like it). G17 smells like “glue” … must be the cyclohexane. Not strong as Pliobond, and does not linger.

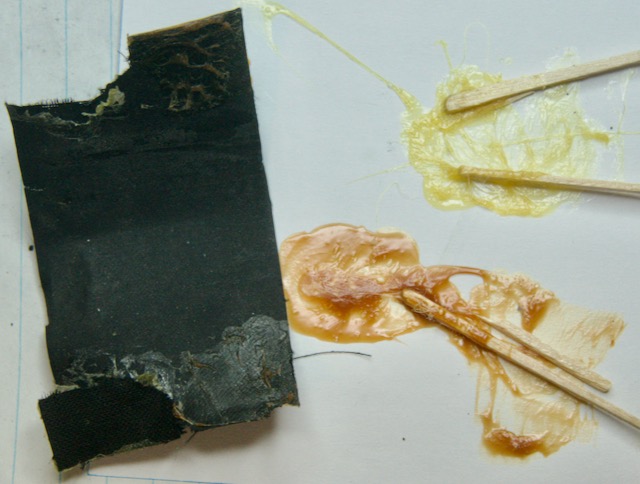

G17 is yellow and it appears to have less solids.

Tackiness … it is thinner. Probably due to having less solids in it, so it only produces very light, if any, strings . This does make it easier to apply as I don’t have to clean up as many trailing glue strings all over the place.

Reposition time … I put glue on one rubber side of an old shutter curtain, let it dry for about 30s, then rolled it over to attached it to the other end of the curtain. The Pliobond remained rubbery longer than the G17, so seems to give me more time to move it about.

The G17 glue on the paper hardened faster than the Pliobond, though both remained rubbery after 5 minutes sitting there.

Throughout this unscientific testing the smell of Pliobond covered up whatever the G17 was giving off, but I will say that it most people will be happy with the odor level using G17.

I added glue to the other end of the curtain and put them back together. After about 15 minutes I pulled the curtain apart to see how the glue held up … both stuck pretty good. The G17 stuck so well the curtain ripped … appears that the curing time is shorter, but I was still able to pull off the ripped part with a little more force.

OK, so I tried it on real job … I put a set of new curtains on the next Minolta-35. As it sets faster I had to speed up my work flow, but it was not so fast that I could not make adjustments to line up the curtain lath. Was able to clean off excess glue using IPA.

Ah, made a positioning error with one of the curtains … next day I removed it. The G17 held on very good. I was still able to slowly remove the curtain without ripping it. IPA was able to clean off the glue.

Overall … I like the G17, so now you UK’rs got some new glue.

It adhered well to the rubber curtain and rollers, much less smelly, and made a pretty good bond in a shorter time … though I probably it will not replace my Pliobond as I have a friggn giant container of it that will last me a couple of years …